Winners in fashion retailing need to optimize inventory and boost supply chain agility

When we talk to retailers about what its top of their “wish list”, real-time inventory visibility is one of the things they most often mention. Without it, it’s not possible to support omnichannel scenarios, of course.

But beyond that, it’s not about just gaining real-time inventory visibility it’s also about optimizing the overall inventory management process, because this has a crucial impact on costs and the financial performance for the retailer.

H&M, the Swedish fast-fashion retailer knows this only too well.

As was reported earlier, H&M built up approximately $4bn in excess inventory last year. In its latest financial results, the company says it is now having to take drastic action in the form of heavy clothing discounts in the third quarter of 2018. Year-on-year, inventories rose by 13 percent.

“The inventory level is still too high and will lead to increased markdowns in relation to sales in the third quarter, compared with the same period last year,” said Nils Vinge, the retailer’s head of investor relations, during a recent conference call with investors.

That’s great news for bargain-seeking customers of course. But in today’s fast-moving fashion retailing industry the window of opportunity to sell products at full price is getting shorter.

Today, we see that the concept of seasons is fast becoming a thing of the past. Retailers are continuously launching new products, new styles, and new categories. So it is very important to reduce the “time-to-shelf” as much as possible.

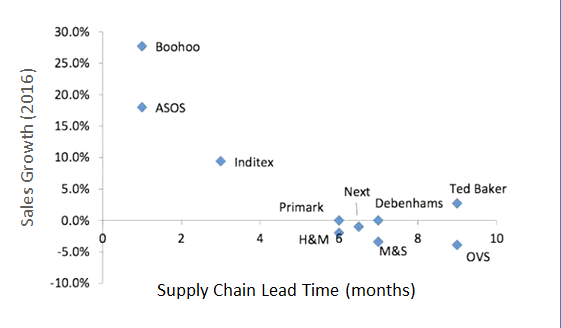

As you can see from the chart on the right, H&M’s lead times are better than other large fashion retailers but still twice as long as those of Inditex, its main rival, best known for its Zara brand.

Inditex, which is often seen to be the trendsetter in the fast fashion, has short lead times but not as short as the online retailers ASOS and Boohoo.

ASOS stocks over 60,000 items at any given time, allowing it to constantly update its inventory with ‘new in’ products, designed to appeal particular to millennial customers.

H&M recognizes that to compete better with online rivals, H&M needs to shorten its lead times, which will enable it to do more buying in season. It also wants to improve the balance and precision of its assortment. Together, it hopes these initiatives wil lhelp it achieve more full-price sales and so improve the company’s financial performace.

The Need for Speed

It is clear to me that being able to move inventory quickly through your supply chain is now a critical success factor in fashion retailing as it enables you to capture more full-price sales.

The warehouse can often be a bottleneck in your supply chain which is why Openbravo has developed a solution that helps manage different warehouse scenarios, ranging from very simple to highly complex set-ups.

Whether you have a store or a very large warehouse, you can define routing areas, travel sequences, bin capacities, and so on. This enable you really optimize travel paths and you are able to prioritize and assign tasks to the right staff, make best use of your warehouse space, and optimize inventory.

Openbravo’s warehouse management solution uses exactly the same mobile technology as our POS solution, so it can be used from a variety mobile devices. it is responsive web technology that is offline-resistant, which helps increase agility and provides warehouse associates with the tools they need to help minimize and reduce errors and ultimately increase accuracy.

To find out more about how Openbravo Commerce Cloud can meet the demandinng requirements of omnichannel fashion retailers, replay our webinar Omnichannel leader or laggard? What’s your choice as a fashion retailer?